Stainless steel has many uses across several industries. Different alloys are better suited to different applications, but they’re not always ready for use as they are. In some cases, steel needs to be hardened to increase its durability or otherwise make it ready for its intended use. At Alliant Metals, we supply stainless steel in New England, ready for whatever application or industry you need.

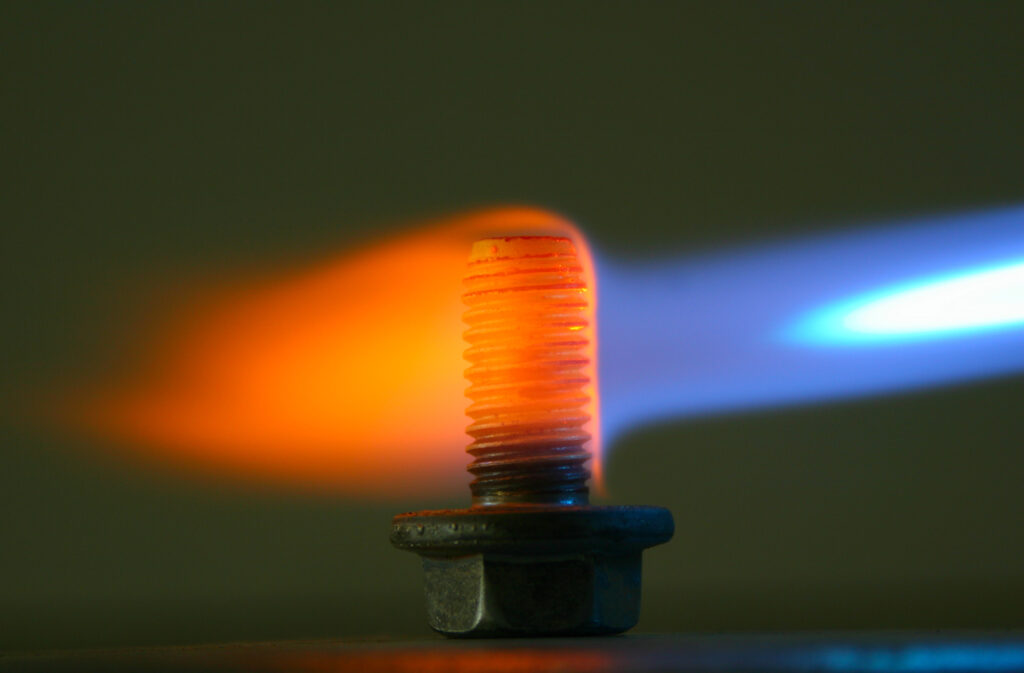

Heat treatment is the most common method for hardening steel. The process starts by heating the steel to a high temperature and then rapidly cooling it back to room temperature. The rapid cooling, also called quenching, changes the internal structure of the steel. The changed structure makes the steel harder but also more brittle. The heat treatment process is used on multiple types of steel to bring steel to various hardness levels. The exact temperature and the cooling rate will change depending on the type of steel and the intended hardness.

This method hardens the surface of the steel while maintaining a ductile core. To achieve this effect, the steel is heated in the presence of a carbon-rich material, which then diffuses onto the surface of the steel. The final step is to quench the steel to harden the surface.

This method is used to harden a specific area of the steel, usually on small, intricate parts. An electrical current goes through the steel to heat the particular area. Quenching the heated area produces a wear-resistant surface area.

These last two methods are similar to case hardening in that the steel is heated with another substance. Nitriding uses nitrogen gas, and carbonitriding uses both carbon and nitrogen gases. When the steel is heated, the gases react with the surface, producing a hard and wear-resistant layer.

Alliant Metals has been supplying New England stainless steel for uses across multiple industries for over 30 years. Our knowledgeable staff will work with you to find the right stainless steel products for your applications and projects.